Page 33 - Labstil ENG Katalog

P. 33

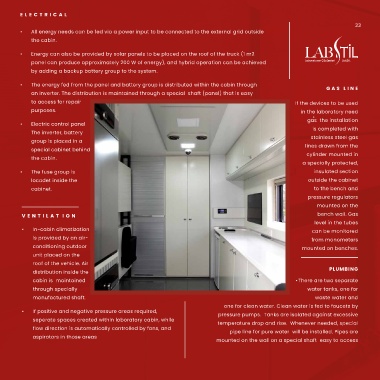

E L E C T R I C A L

32 CABIN CHASIS 33

• All energy needs can be fed via a power input to be connected to the external grid outside

the cabin.

• The cabin chassis, on which the cabin will sit on ,and which

is mounted on the vehicle’s own chassis, is manufactured by

• Energy can also be provided by solar panels to be placed on the roof of the truck (1 m2

using U profile and L profile materials.

panel can produce approximately 200 W of energy), and hybrid operation can be achieved

by adding a backup battery group to the system.

• The energy fed from the panel and battery group is distributed within the cabin through

GAS LINE

an inverter. The distribution is maintained through a special shaft (panel) that is easy

CABIN

to access for repair If the devices to be used

purposes.

• Body (laboratory cabin) placed on the cabin chassis in the laboratory need

mounted on the vehicle chassis. It consists of five separate gas the installation

• Electric control panel

layers is completed with

The inverter, battery

stainless steel gas

group is placed in a

• 1st layer: Glass reinforced polyester, 1.5 - 2.5 mm

lines drawn from the

special cabinet behind

cylinder mounted in

• 2. Layer: Up to 8.0 mm, wooden plate, metal plate, or lead the cabin.

a specially protected,

plate

• The fuse group is insulated section

• 3rd layer; XPS or Polyurethane heat insulation layer up to

locadet inside the outside the cabinet

40.0 mm

cabinet. to the bench and

pressure regulators

• Layer 4: Up to 8.0 mm, wooden plate, metal plate, or lead

mounted on the

plate.

bench wall. Gas

V E N T I L A T I O N

• 5th layer: Glass reinforced polyester, 1.5 - 2.5 mm level in the tubes

• In-cabin climatization

can be monitored

is provided by an air-

from monometers

conditioning outdoor

mounted on benches.

unit placed on the

roof of the vehicle. Air

• The entrance door can be designed as manual, pneumatic or electric, which can be controlled by a remote control

PLUMBING

distribution inside the

unit and by the button in the driver’s cab. A motorized or manual metallic staircase with 2 or 4 steps that folds under cabin is maintained There are two separate

www.labstil.com.tr • covering can be PVC, Epoxy coating or ceramic if desired. • through specially pressure pumps. Tanks are isolated against excessive

the entrance door when driving is used, and the motorized staircase cannot be closed while the door is open. The floor

water tanks, one for

waste water and

manufactured shaft.

MDF material (laminated or lacquered) is used for cabinets and drawers. All cabinets and drawers are locked with a push

one for clean water. Clean water is fed to foucets by

If positive and negative pressure areas required,

lock. Worktops and sinks a r e made of acrylic material.

• If desired, a rest a r e a (bed, TV, seating unit) can be created. Monitors suitable for the devices to be used are mounted seperate spaces created within laboratory cabin, while temperature drop and rise. Whenever needed, special

flow direction is automatically controlled by fans, and

pipe line for pure water will be installed. Pipes are

on the bench walls. aspirators in those areas

mounted on the wall on a special shaft easy to access